Electronic precision field

- Resistant to high and low temperatures

- Corrosion resistant

- Wear-resistant and pressure-resistant

- Safe and non-slip

Application scenarios

Anti-static floor VS Conductive floor

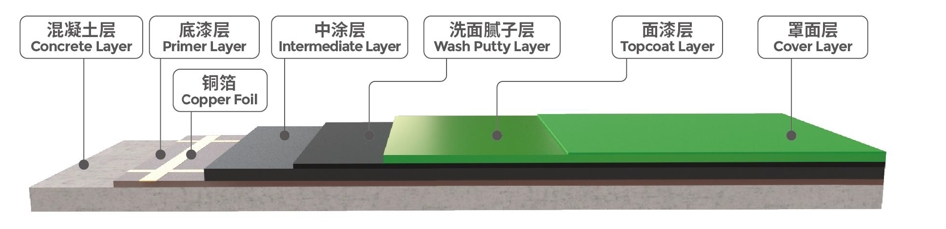

Taimu anti-static floors can be specifically divided into two categories: anti-static floors and conductive floors. Although both types of floors have the function of eliminating static electricity, the difference in their main resistance values leads to differences in the rate and degree of their effects.

1、Anti-static floor

The anti-static type is also called the dissipative type, with a resistance value of 10⁶~10⁹. It is characterized by a small current generated, which is introduced into the ground in the form of dissipation. Therefore, it is suitable for production environments with 220V~380V and higher voltage operations.2、Conductive floor

The resistance value of the conductive anti-static floor is 10⁴~10⁶. It can quickly absorb charges and dissipate them into the ground. It is mainly aimed at weak current products. Static accumulation is extremely harmful to such precision products and needs to be eliminated in time.Product Series

Item Number | Name | Packaging Specifications | Performance | ||

|---|---|---|---|---|---|

Base Agent kg | Curing Agent kg | Aggregate kg | |||

| TM-22 | Solvent-free Polyurethane High Elastic Self-leveling Paint (Thick Coating Type) | 20 | 5 | / | Environmentally friendly material, high elasticity, crack resistance, excellent compression resistance; easy to apply, good leveling property, various colors. Suitable for hospitals, pharmaceutical factories, shopping malls, workshops, schools and other places. |

| TM-25 | Solvent-free Epoxy Colored Sand Self-leveling Paint (Thick Coating Type) | 16 | 3.3 | 5.7 | |

| TM-31 | Solvent-free Epoxy Anti-static Self-leveling Topcoat (Dissipative Type) | 20 | 4 | / | 6H hardness, super wear resistance, excellent corrosion resistance, good leveling property, permanent conductivity. Suitable for electronics factories, power distribution rooms, electronic component assembly workshops and other anti-static places. Suitable for batch scraping treatment of the ground before painting anti-static floor topcoat, improving the conductivity of anti-static topcoat (water-based material, zero VOC emission). |

| TM-32 | Solvent-free Epoxy Anti-static Self-leveling Topcoat (Conductive Type) | 20 | 4 | / | |

| TM-33 | High Solids Epoxy Anti-static Topcoat (Thin Coating Type) | 20 | 5 | / | |

| TM-34 | High Solids Epoxy Anti-static Anti-corrosion Topcoat (Thick Coating Type) | 20 | 5 | / | |

| TM-35 | High Solids Epoxy Anti-static Intermediate Coat (Thin Coating Type) | 20 | 5 | / | |

| TM-37 | Solvent-free Polyurethane Ultra-wear-resistant Anti-static Topcoat (Thin Coating Type) | 2 | 5 | 3 | |

| SX-03 | Conductive Putty | 4 | 20 | / | High conductivity, easy to use, can be applied by batch scraping after mixing; anti-static wall surface, environmentally friendly material. Suitable for anti-static walls in electronics factories and anti-static walls in powder workshops. |

| SX-13 | Water-based Epoxy Anti-static Wall Paint (Thin Coating Type) | 15 | 5 | / | |

English

English

简体中文

简体中文

Thai

Thai

Vietnamese

Vietnamese